3servo system

Maximum pouch making shot:

- 240 CPM (three-side-seal pouch making)

- 240 CPM (standing pouch making)

- *300 CPM is available by additional equipments. (three-side-seal pouch making)

- *Pouch making capacity depends on film material and thickness.

Stand-out stand-ups at incredible speeds

- Standing pouch making at an outstanding high-speed of 240 CPM *300 CPM is available by additional equipments.

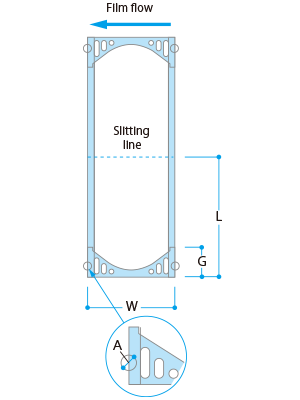

- Three main frame lengths are available to accommodate your specific use and available spaces.

- Available with optional servo drive for the film feed roller unit.