- Options/Others

-

"Zero-Stop Conveyor" accumulates pouches after pouch making according to the set number of pouches and works in conjunction with the "Vibration Device" to reduce the time and labor required to sort the pouches.

Overview and Feature

In pouch making machines capable of high-speed pouch making, finished pouches are conveyed at high speed even in the final process. The "Zero-Stop Conveyor" was developed to accommodate such high- speed pouch making and to improve the efficiency and convenience of pouch making operations. This page provides an overview of the "Zero-Stop Conveyor" (video available).

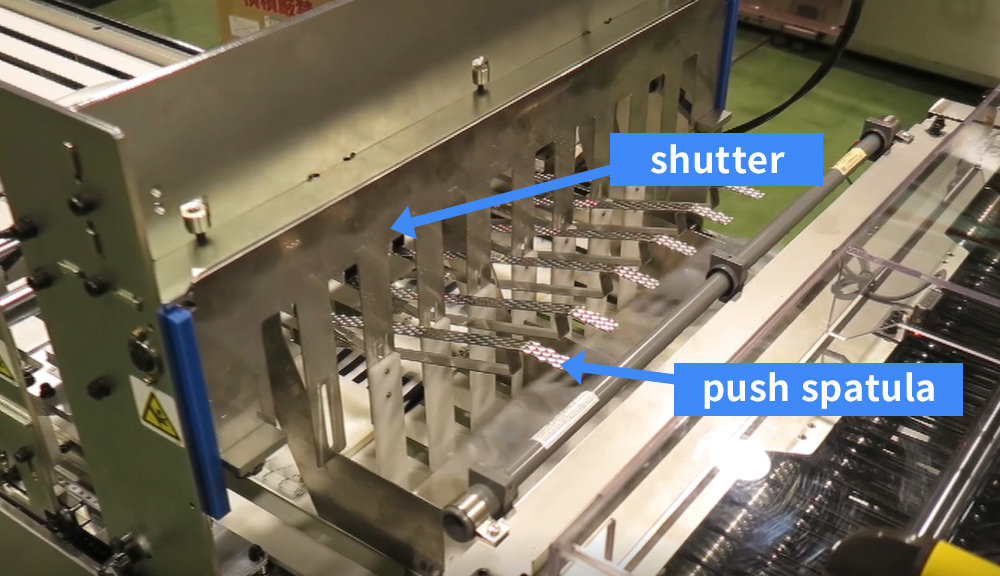

- When pouches that have been finished making are discharged from the raw material side (upstream) onto the "zero stop conveyor," they are stopped by the "shutter" and a set number of pouches are accumulated. During pouch accumulation, vibration is applied by a vibrating device to promote bag alignment. (Vibration is applied from the upstream).

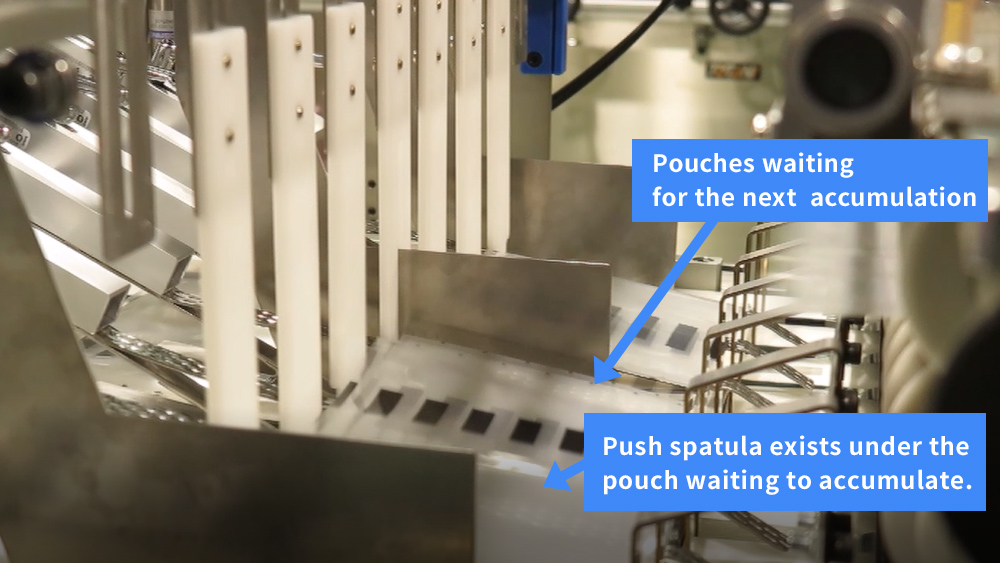

- When the number of pouches accumulated reaches a set number, the "push spatula" presses down the bundle of bags accumulated. During this time, pouches after making continue to be discharged from upstream, and pouches waiting for the next accumulation are temporarily accumulated on the top surface of the "push spatula".

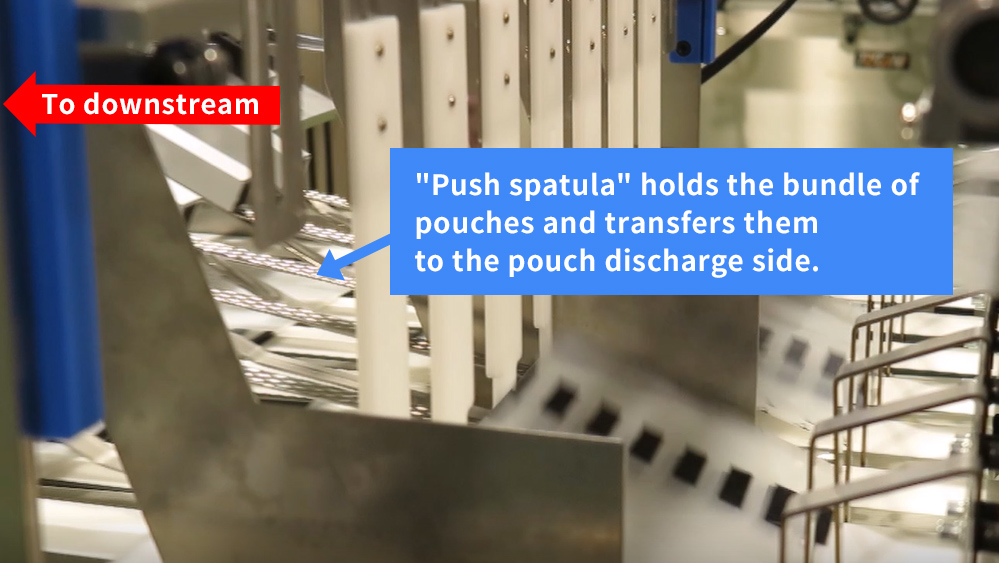

- Next, the "shutter" rises, and the "push spatula" holds the bundle of pouches and conveys them to the pouch discharge side (downstream).

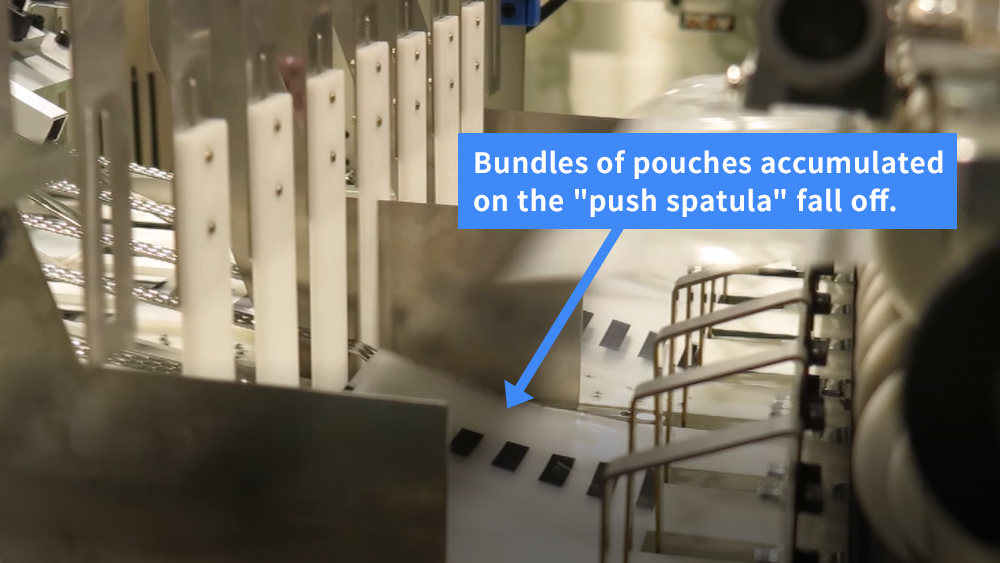

- Immediately after a bundle of pouches passes the "shutter" position, the "shutter" is lowered. At the same time, bundles of pouches accumulated on the "push spatula" are stopped by the "shutter" and fall into place. The next bundles of pouches after pouch making are accumulated on top of the shutter.

The "push spatula" returns to the standby position (Process 1) after finishing conveyance to prepare for the next conveyance.

Processes 1) through 4) are repeated while the pouch making machine is in operation. In this process, there is no need to "pause" and pouches of the set number of sheets are smoothly discharged in a neatly aligned state. It reduces the time and labor required to line up pouches after pouch making, and also supports higher pouch making speeds. Improved pouch making machine utilization rate and work efficiency will contribute to reduction of labor costs.

Watch the video of the smooth operation of the Zero-Stop Conveyor! (Japanese subtitles)

Specifications may differ slightly depending on the model equipped with this device.- BH series is equipped with a "defective bag separation conveyor" unit in the front-end process, which has the advantage of being able to distinguish between good and defective lines.

- HK series, the standard specification requires the unit to stop several times when the set number of bags is reached, but the "Zero-Stop Conveyor" eliminates the number of stops and improves productivity.

* Appearance, specifications, prices, and other information are subject to change without

- When pouches that have been finished making are discharged from the raw material side (upstream) onto the "zero stop conveyor," they are stopped by the "shutter" and a set number of pouches are accumulated. During pouch accumulation, vibration is applied by a vibrating device to promote bag alignment. (Vibration is applied from the upstream).

Why Totani?