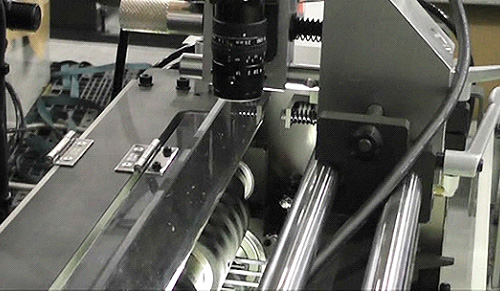

- Film position control and cut section

-

Get More Speed and Accuracy on your Cutter Control System!

What is the Totani "Real Time Cutter Control" technology?Overview and Feature

The "Real Time Cutter Control" is a new feature of our “Double Cut System,” and it aligns the cutter position exactly to the center of the round corner on a real-time basis. The “Double Cut System” has been highly regarded for the beautiful finish without generating burrs in corner cut unit, ensuring the safety of consumers and improved the value of the pouches.

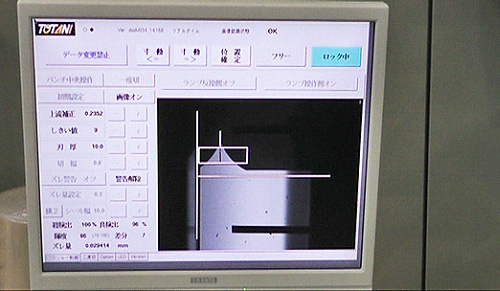

The basic principle of the technology is a combination of the "High-precision CCD Camera" which monitors the shape of the round corner, the "Computerized Image Analysis" and the "Cutter Control System" which controls the cutter position accurately with a servo motor.

When a cutter position should be changed due to misalignments of the print for instance, the evolved high speed image analysis moves the cutter position so that the cutter cuts right in the middle of the round corner precisely and in real time. The new “Real Time Cutter Control System” does complete the image analyzing significantly faster with our unique processing technology than the existing “Cutter Control System” does.

The Individual Cutter Up-down Servo Control also enhances this new feature. Since the cutter up-down motion is controlled and driven separately from the heater up-down drive, a servo motor for the cutter up-down can optimize the cutting speed and time in accordance with the “Real Time Cutter Control.” This technology has also resolved the issue with time-optimization which is linked to the production speed and achieved the ultra high speed.Totani's original "Cutter Control System," which aligns the cutter to the round corner quickly and accurately and eliminate the burrs/steps to achieve the beautiful and safe finish, reduces further film waste and loss and contributes sustainability.

<Positioning high-precision CCD camera>

<Real Time High Speed Image Analysis>

* The information on this site is subject to change without notice.

* The maximum cycle per minute described is verified under the certain conditions.

* Actual production speed may vary depending upon materials and others.

* Please consult with sales dept. for further information.

Why Totani?