- Film position control and cut section

-

Totani's original Print smoothing function enables stable working accuracy in finished size, sealing width and notching of pouch.

Overview and Feature

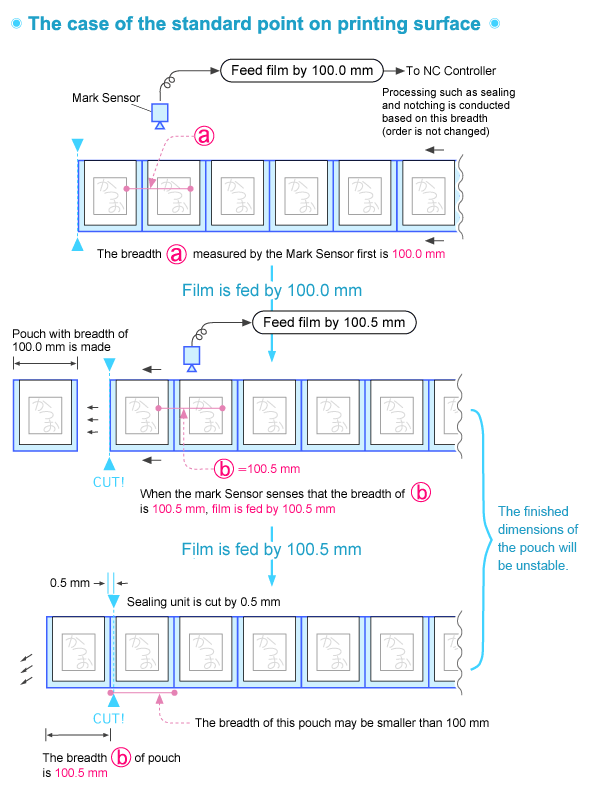

Mark Sensor in pouch making machine (*1), reads printing and non-printing areas and change in density of printing color to feed film at constant pitch. In other words, the Mark Sensor in pouch making machine always measures film pitch based on one point on printing surface. The film pitch is transmitted to the NC controller as the finished breadth of pouch. Then, a rubber feeding roller feeds film (see the Figure).

The problem is that the distance between printing surfaces (pitch) on film varies in real manufacturing. When the standard distance between printing surfaces (pitch) is defined as 100 mm, the distance between printing surfaces (pitch) always varies repeatedly within a tolerance of one-tenth of a millimeter (e.g. 100.5 mm, 99.8 mm and 100.3 mm).

Of course, the value measured by the Mark Sensor can be used as a standard to feed film (the setting of printing control). However, in this setting, if the distance between printing surfaces (pitch) is 100.5 mm when the standard breadth of pouch is 100 mm, the Sensor orders the Controller to feed film by 100.5 mm. Then, the finished breadth of pouch is 100.5 mm.

In this case, the sealing breadth (the finished breadth) of the next pouch is reduced by tolerance of 0.5 mm. Thus, the finished breadth of pouch varies widely (see the Figure).

Totani's Print smoothing function senses the variation in the distance between printing surfaces (pitch) to control film pitch. For example, when the distance between printing surfaces (pitch) is 100.5 mm as above, the Sensor orders the Controller to feed film by 100.2 mm. Meanwhile, when the distance between printing surfaces (pitch) in the next pouch is 99.8 mm, the Sensor orders the Controller to feed film by 99.8 mm as is (see the Figure).

In the setting of Print smoothing control, the finished breadth of pouch does not vary much with change in the distance between printing surfaces (pitch), with respect to the standard of 100 mm. At the same time, sealing width becomes stable. Then, the quality of particular processing such as notching becomes stable (see the Figure).

This control method requires pouch making data which was accumulated in the past. Totani's pouch making machine is highly evaluated in control technology domestically and internationally.

(*1) Mark Sensor is an optical control sensor which feeds film at a constant pitch by reading printing and non-printing areas on film and change in density of printing color.

* The information on this site is subject to change without notice.

Why Totani?